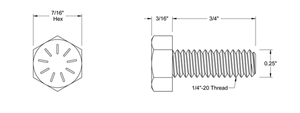

Custom Parts

Whether it's a standard fastener in a special

material or a completely custom component,

we understand that these are critical

pieces of an application.

Adding Value

We work with a carefully selected set of manufacturers to ensure that you receive the same high quality service and competitive pricing that you expect from Grampian Fasteners.

Grampian Fasteners adds value by selecting the best manufacturer based on their process capability, material availability and workload to match your requirements, thus removing the procurement burden. We are in regular communication with the manufacturers to ensure that parts are delivered on time.

Quantities

There are no minimum quantities required but please bear in mind that there are base costs for setup with any custom part.

Breakdown Service

Emergency 24-hour breakdown service may be available depending on material availability.There are no minimum quantities required but please bear in mind that there are base costs for setup with any custom part.

Processes

Precision Machining

Hot Forging

Thread Rolling

Heat Treatment

Laser Marking

Not in the list?

Please ask, we will try to meet your needs.

Email

Surface Coatings

The main surface coatings required by our customers include;

Zinc electro-plating and passivation

Zinc Nickel

Xylan / PTFE

Hot Dip Galvanised

Not in the list?

Please ask, we will try to meet your needs.

Email

Materials

Carbon and Alloy Steels: ASTM A193 B7/L7, A194, A320

Stainless Steels: ASTM A194 B8/B16

Nickel Alloys: Inconel 600, 601, 625, 718 AND 925, Monel 400/K500, Hastelloy, Zeron 100

Titanium: Grades 2 and 5

Aluminium

Brass

Not in the list?

Please ask, we will try to meet your needs.

Email

Testing & Certification

Certification to BS EN 10204 3.1

Third-party certification to BS EN 10204 3.2 (Lloyds, DNV and Burea Veritas) available on request

Not in the list?

Please ask, we will try to meet your needs.

Email